PREMIUM PADS

A STATE-OF-THE-ART MANUFACTURING FACILITY

Opened in 2007, our pad manufacturing facility plays a key role in the design and production of an extensive range of high-tech, top-quality polishing pads. During the past two years, we have continued upgrading our pad manufacturing facility, both by implementing new systems aswell as by optimising existing ones. A computer-controlled SpiderPad calibration machine, a fully automated high-frequency milling system with an integrated packaging line and a high performance die-cutter are among the latest and most important machineries in which we have invested.

GERMAN EFFICIENCY

The majority of our polishing pads are manufactured for industrial paint finish applications in modern car plants. Distinctive cost awareness among our industrial clients, and the high quality standard expected from our pads, have had a lasting impact in shaping our manufacturing processes. Currently, our facilities have a maximum daily production capacity of 10,000 polishing pads. Customers from all over the world recognize and appreciate our pads “Made in Germany”.

INNOVATIVE AND STYLISH POLISHING PADS

Over 30% of the polishing result depends on the proper use of the right pad. This insight and over 50 years of expertise in the paint finish industry have allowed us to explore new grounds in the development of polishing pads: Innovations such as the calibrated Spider Polishing Pads have been widely adopted in the automotive industry and bodyshops. The shape and form of our pads are expressed by a unique and stylish design. The attractive and elaborate “Abrafix“ patterning on the backside of the pad implies instant brand recognition and, for many customers, an undisputed hallmark of quality.

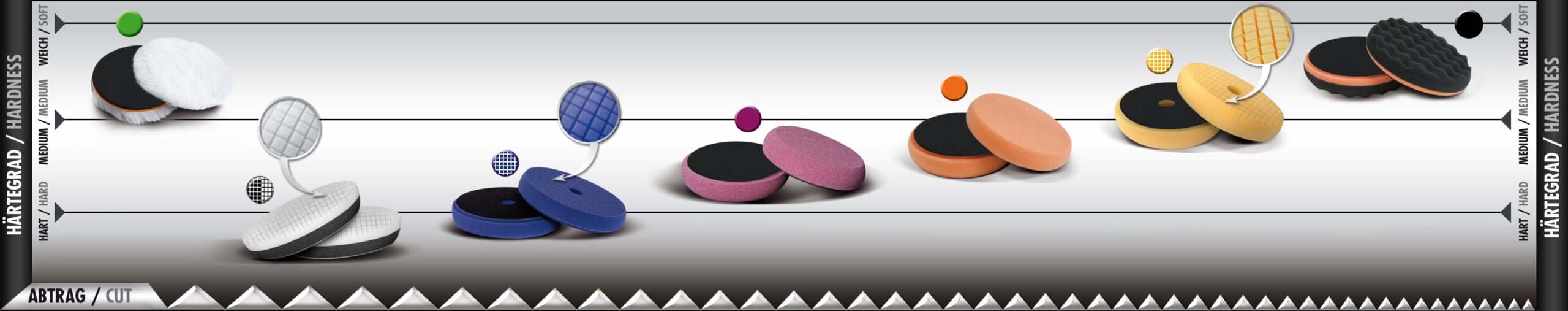

PRODUCTS

-

SANDWICH-SPIDERPAD BLACK/WHITE

-

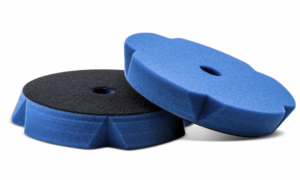

SPIDERPAD NAVY-BLUE

-

POLISHING PAD PURPLE

-

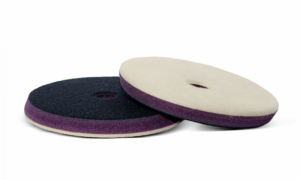

SPIDER PAD PURPLE

-

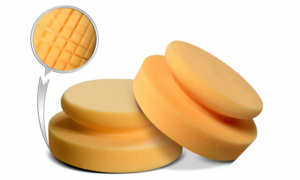

POLISHING PAD ORANGE

-

PREMIUM SOFTOUCH-TOPWOOL WHITE

-

NATURAL WOOL CUTTING PAD

-

MICROFIBER CUTTING PAD

-

SOFTOUCH-WAFFLE PAD BLACK

-

NEO SPIDERPAD HONEY

-

NINJA CUTTING PAD RED

-

NINJA FINISH PAD BLUE

-

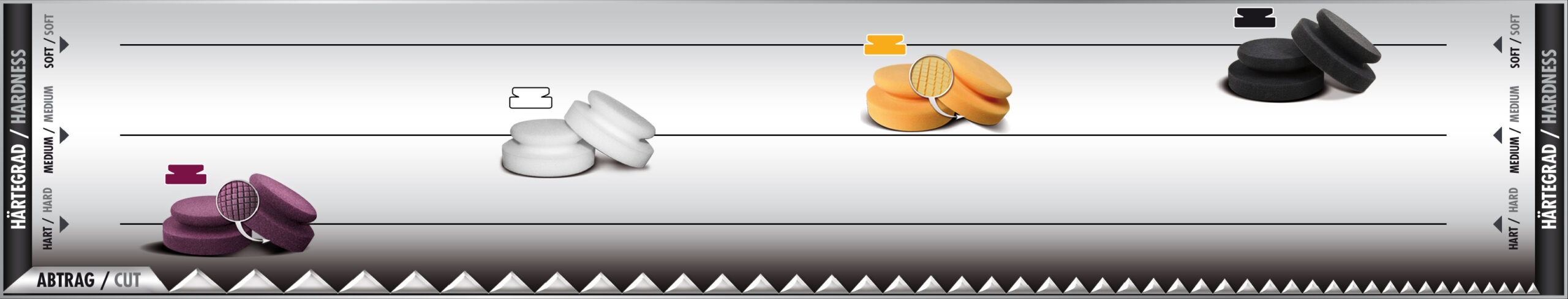

MINIPAD NAVY-BLUE

-

MINIPAD PURPLE

-

MINIPAD ORANGE

-

SPIDER CLEANING PUCK PURPLE

-

HANDPUCK WHITE

-

NEO SPIDERPUCK HONEY

-

HANDPUCK BLACK